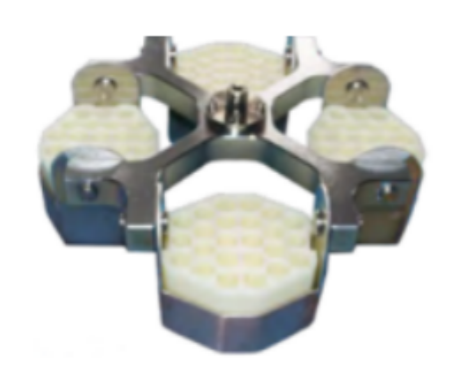

Refrigerated Centrifuge

⭐ The function of a centrifuge is to use centrifugal force to separate,concentrate, or purify substances.

⭐ A refrigerated bag centrifuge is a specially designed centrifuge used for low-temperature centrifugation of frozen bags, particularly blood component bags. It is commonly used for the separation and purification of blood and temperature-sensitive biological samples.

⭐ With a maximum speed of 5500rpm and a maximum RCF of 5952 xg,it meets a wide range of experimental and separation needs.

⭐ The core performance of a centrifuge depends not only on the main unit itself but also heavily on the type and performance of the rotor it is equipped with.

Angle Rotor:

Angle Rotor:

The centrifuge tubes are held at a constant angle relative to the central axis.

As shown in the diagram, each tube fits into a fixed slot, and the angle cannot be adjusted.

The smaller the angle between the centrifuge tube and the rotor axis, the higher the centrifugation efficiency.

Swing-out Rotor:

Swing-out Rotor:

In this design, the buckets swing out during rotation rather than remaining fixed.

Initially in a vertical position, the buckets swing out to a horizontal position as the rotor spins,

allowing the sample to experience centrifugal force and sediment accordingly during this motion.

⭐ The key technical specifications of a refrigerated centrifuge usually include:

1️⃣ Maximum Speed (RPM- Revolutions Per Minute):

This indicates the highest speed the rotor can reach. A higher RPM generally means better separation efficiency, but the sample's tolerance must also be considered.

2️⃣ Maximum Relative Centrifugal Force (RCF):

RCF reflects the actual centrifugal force more accurately than RPM. It has a direct effect on how fast and how well the particles in the sample are separated.

3️⃣ Temperature Range:

Typically from -20'C to +40'C. A refrigerated centrifuge can maintain low temperatures to prevent heat buildup during spinning, which helps protect temperature-sensitive samples from degradation.