Classifications of Medical Sterilizer

Pressure Steam Sterilizer (Autoclave)

It utilizes high-temperature saturated steam to denature microbial proteins within a specific time frame, thereby inactivating microorganisms and achieving sterilization of moisture and heat resistant items.

Dry Heat Sterilizer

It employs circulating hot air to achieve sterlization or disinfection through thermal effects.

Ethylene Oxide (EO) Sterilizer

Under specific conditions of temperature, pressure, and humidity, ethylene oxide gas is used to interact with items in the steriization chamber, denaturing microbial proteins and genetic material. thereby inactivating mcroorganisms and achievng sterilization.

Low-Temperature Formaldehyde Vapor Sterilizer

Under specific conditions of temperature, pressure, and humidity, formaldehyde gas is employed to interact with items in the sterilization chamber, denaturing microbial proteins and genetic material, thereby inactivating microorganisms and achieving sterilization.

Hydrogen Peroxide Low-Temperature Plasma Sterilizer

It vaporizes hydrogen peroxide to interact with items in the sterilization chamber, denaturing microbial proteins and genetic material,thereby inactivating microorganisms and achieving sterilization.

Advantages of Autoclave

MG-VS35 / 50 / 75 / 100

MG-VS35 / 50 / 75 / 100

MG-HS150 200 280 400 500

MG-HS150 200 280 400 500

🔸 Efficient and Rapid Sterilization:

15-30 minutes to complete sterilization, while dry heat sterilization takes over 10hs.

🔸 Strong Penetration without Dead Zones:

Steam can deeply penetrate porous materals and complex instruments, suitable for intricate experimental devices.

🔸 Reliable Sterilization Efficacy:

Eradicate various pathogens including bacteria, viruses, and fungi, ideal for sterilizing high-risk items such as surgical instruments and syringes.

🔸 Eco-Friendly and Pollution-Free:

Utilizing non-toxic, chemical residue-free steam as the sterilizing medium, it avoids potential toxicity risks associated with chemical sterilants.

🔸 Energy-Saving and Cost-Effective:

Consuming significantly less energy than dry heat sterilizers.

🔸 Broad Application Scope:

Capable of processing a wide range of items including meta instruments, glassware, dressings, rubber products, culture media, and biological waste. etc.

35L / 50L / 75L / 100L Available

Working Pressure: 0.22Mpa

Temp Adjustment: 105-134°C

Fully Stainless-Steel Structure

150L / 200L / 280L / 400L / 500L Available

Working Pressure: 0.22Mpa

Temp Adjustment: 40-134°C

Drying Function For Medical Dressing Drying

Applications

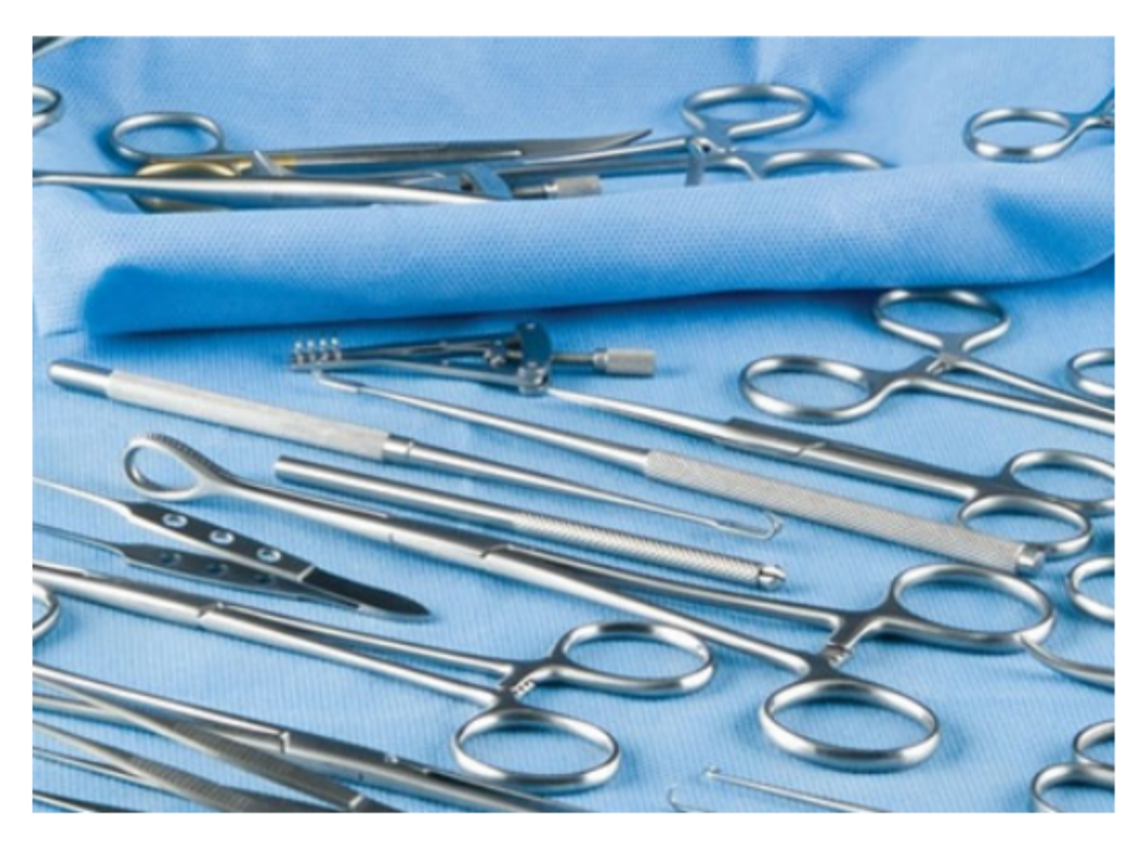

Pressure Steam Sterilizer (Autoclave)

Used to sterilize heat- and moisture-resistant items such as metal instruments, dressings, glassware, porcelainware, and rubber products.

Dry Heat Sterilizer

Used to sterilize heat-resistant but moisture-sensitive items like metal instruments, glassware, powders, oils, and some rubber products.

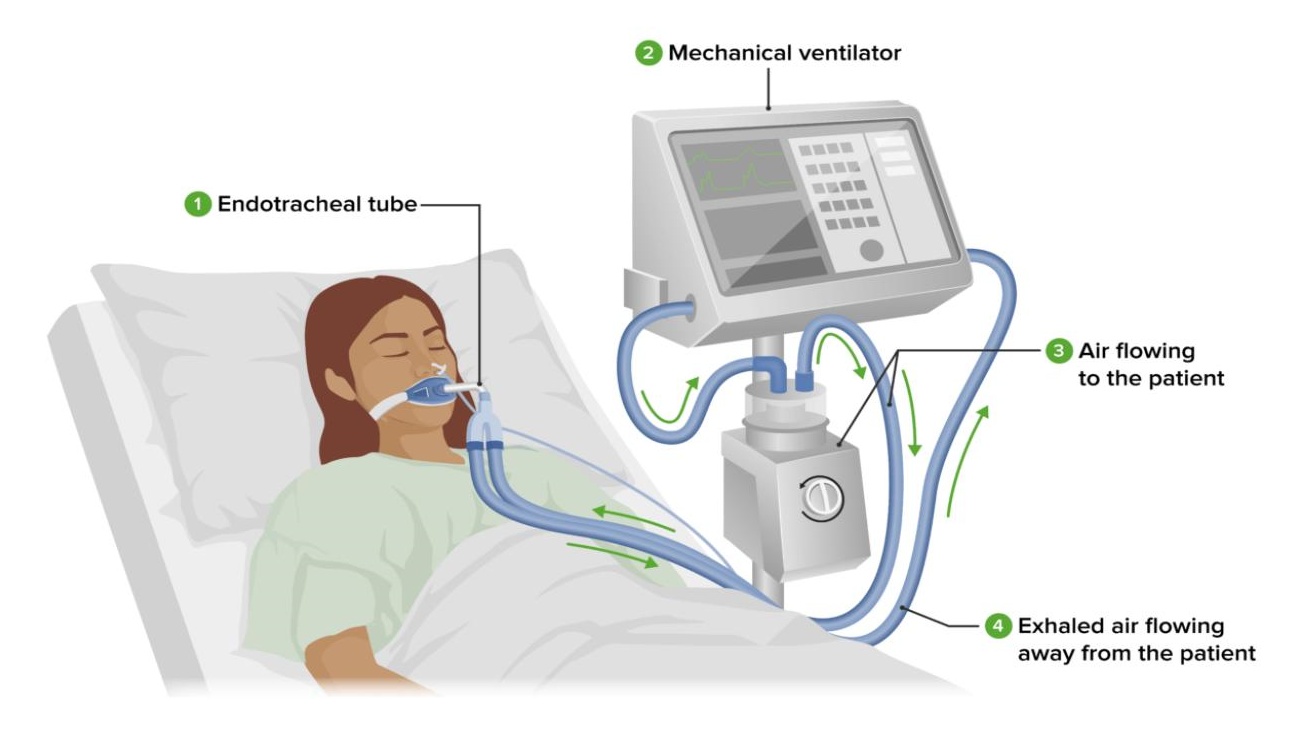

Ethyene Oxide (EO) Sterilizertilizer

Utilized for sterilizing medical devices that can tolerate ethylene oxide, It effectively inactivates bacteria, fungi, spores, viruses, and other microorganisms on surfaces without damaging the items.

Low-Temperature Formaldehyde Vapor Sterilizer

Used for sterilizing medical devices that can tolerate formaldehyde.

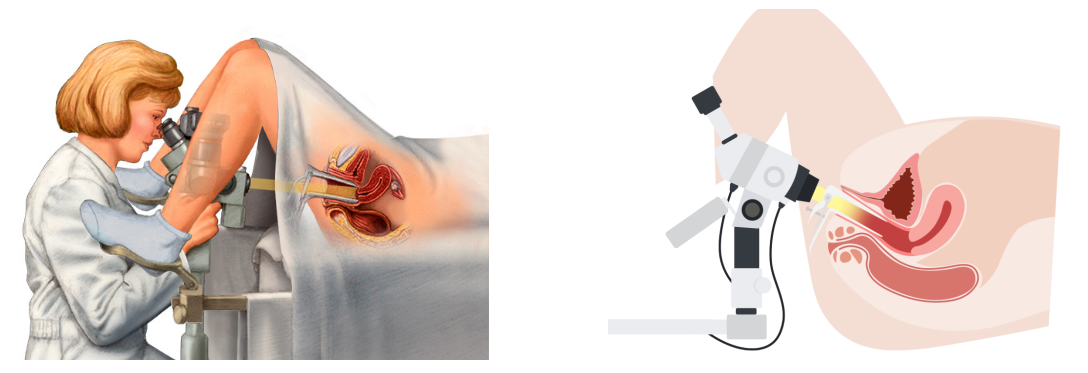

Hydrogen Peroxide Low-Temperature Plasma Sterilizer

Applied for sterilizing medical devices that can withstand hydrogen peroxide,such as endoscopes, heat-sensitive instruments,various metal struments,glassware. etc.